This month continues discussion about familiar and frustrating challenges as concrete producers. Next month we’ll return to new and exciting technologies!

Mechanicals Matter

If you read my last blog, this header will seem familiar. It bears repeating that no existing software in the world, even those supplemented with artificial intelligence.(AI1) can generate consistent or predictable results if the plant is not maintained. This means no leaking air hoses or cylinders, gates must be free of binding/sticking with a clean, consistent, and dry air supply. Neither can the bins be allowed to frequently run out of material.

A common limitation to improving small load batching performance is the design of many concrete plants. Plant manufacturers make design choices to find the best balance between plant accuracy and production speed for the producer they hope will buy that plant. As plant production volume is top of mind manufacturers build plants with aggregate gates tied together in pairs or in quads by mechanical linkages. Often a single output from the computer releases an avalanche of material into the scale. This works great and delivers fast eight-to-ten-yard loads; two percent tolerance on 33,000-pound target (15K kg) allows for an error of plus or minus 660 pounds (300 kg) which batch computers can reliably hit.

With material falling into the scale at a rate of 2000 pounds/sec (909 kg/sec) (or faster) it takes under a second for a single yard of that material to be plummeting into the scale. If the scale bottom is 12 feet from the gate it takes 3/8 of second for the material to the scale when the gate opens. It can take another 1/2 to 3/4 second for the load cells and electronics to react allowing the computer to detect a weight.

I’ll go on record, if you have a plant with multiple aggregates gates bound together your best first step is too ‘un-bind’ the gates so flow rates are reduced for smaller loads. (It likely will help large loads too!)

Understanding the Causes

There are two types of feed mechanisms used by your batching computer. The first one can be described as ‘closed loop; the ‘loop’ is defined as the computer software periodically ‘reading’ the scale weight as the material flows into the scale. The process is continuous; the feed cycle starts and continues until the material target is achieved. The other type of feed mechanism is ‘open loop’ where the instantaneous scale readings are effectively ignored with the feed mechanism relying on a calculated duration of time to open the gate for the desired amount of material.

The ’open loop’ mechanism goes by multiple names, COMMANDbatch uses the terms ‘time feed’ and ‘jog feed’. It is the same mechanism though, the only difference being the duration the gate is held open. For minimal quantities, i.e., one-to-three scale graduations, the gate is opened for a short period of time (typically one-fourth to three-fourths of a second). For target quantities more than those few scale graduations, but less than the amount required for the ‘closed loop’ process, a longer duration ‘time feed’ pulse is issued.

Regardless of the plant automation vendor, the nature of the batching process and the gate configurations provided from the plant manufacturers (typically single action valves) limits what the automation system programmers can deliver.

Your success in improving small load batching performance is to ensure that the parameters in the automation system are configured correctly to deliver the best results.

What to monitor to improve small batching performance

The software algorithms used for delivering small target values of material are not terribly sophisticated. The introduction of AI into the decision-making process (i.e. how long to open the gate for a target amount of material in the ‘open loop’ mode) shows much promise, it is in fact the primary improvement that can be practically achieved to date. Command Alkon’s Batch AI (formerly MIntelligent Feed) solution is an example.

This does not mean that improvements cannot be made with current software. Using data analytic software such as REDI-VIEW the cause of poor small batching (for COMMANDbatch at least) can be traced to system configuration.

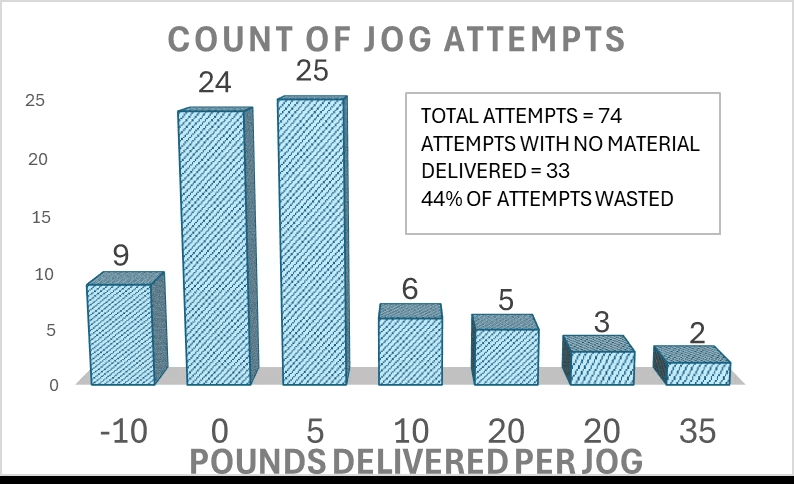

Figure 1 – Results of 57 Loads

Lack of attention to minor things such as time and jog feed setup in COMMANDbatch have an impact. From this result we can see:

- 74 Jog Attempts over 57 Loads for an average of 1.3 Jogs Per Load

- 44% of Attempts delivered zero or less than zero2 material.

- With an estimated settle time of two seconds lost time was over a minute.

This is only for one material at one plant; lost time can add up quickly. ‘Open Loop’ feed algorithms are often the only way to deliver small batches of concrete and monitoring their efficiency is critical to improving small load batching performance. If you do not have the expertise to adjust the system, contact Command Alkon support or other expert resources, the return on investment is easy to justify via saved time.

Closing thoughts

Improving small load batching performance is one thing, maintaining it is just as important. Fortunately, there are providers that can assist you to deliver excellent performance from your production facilities which contributes to better on time performance to your customers.

1 Refer to my blog ‘Applying artificial intelligence to concrete batching’ about what AI can and cannot do.

2 Getting a negative amount delivered probably means the scale was still moving when the system captured the amount delivered. The jog settle time may need to be increased.

As a key architect behind COMMANDbatch and REDI-VIEW, Randy Willaman brings decades of hands-on experience with concrete batching systems. Through his posts, Randy shares his unparalleled expertise and insights with concrete producers looking to maximize their system’s potential. Learn more about his services at willamansolutions.com.