In the world of concrete production, one constant remains—success hinges on reliable, high-quality batching. But today’s producers are grappling with growing challenges: job retention, volatile material costs, and the ever-increasing demand for on-time delivery. Enter Batch AI, a groundbreaking solution designed to transform the batching process and deliver operational excellence.

Resolve Labor Shortages With Confidence

The ready-mix industry is feeling the strain of a dwindling labor pool. Seasoned batchers are retiring, and younger talent is hard to find. With Batch AI, you no longer need to rely on tribal knowledge to keep plants running smoothly. This innovative technology lightens the load for your batchers, automating adjustments and managing variability in real-time.

» Jump to 5:59

New operators stepping into their roles, who may have less experience in the field, can confidently deliver an impact to their organization knowing that Batch AI has their backs. By lowering the barrier to entry and overcoming the complexity of batching, your plant gains resilience in a tightening labor market.

Optimize Production for Consistent, High-Quality Concrete

Batch AI isn’t just about saving time—it’s about delivering consistent, high-quality batches every time. Traditional batching relies heavily on historical data, which limits a business’s ability to adapt to fluctuating plant conditions.

Batch AI, however, continuously analyzes live data—up to 10 times per second—enabling ready mix producers to predict and prevent issues before they occur. This proactive approach eliminates bottlenecks and ensures that each load meets the highest standards of accuracy, consistency, and performance.

» Jump to 12:40

The result? Reliable deliveries that strengthen customer confidence and reduce costly rework or rejected loads. With Batch AI managing the variables, your production becomes a streamlined, predictable process, positioning your business as a trusted supplier in a competitive market.

Reduce Material Costs Without Compromising Quality

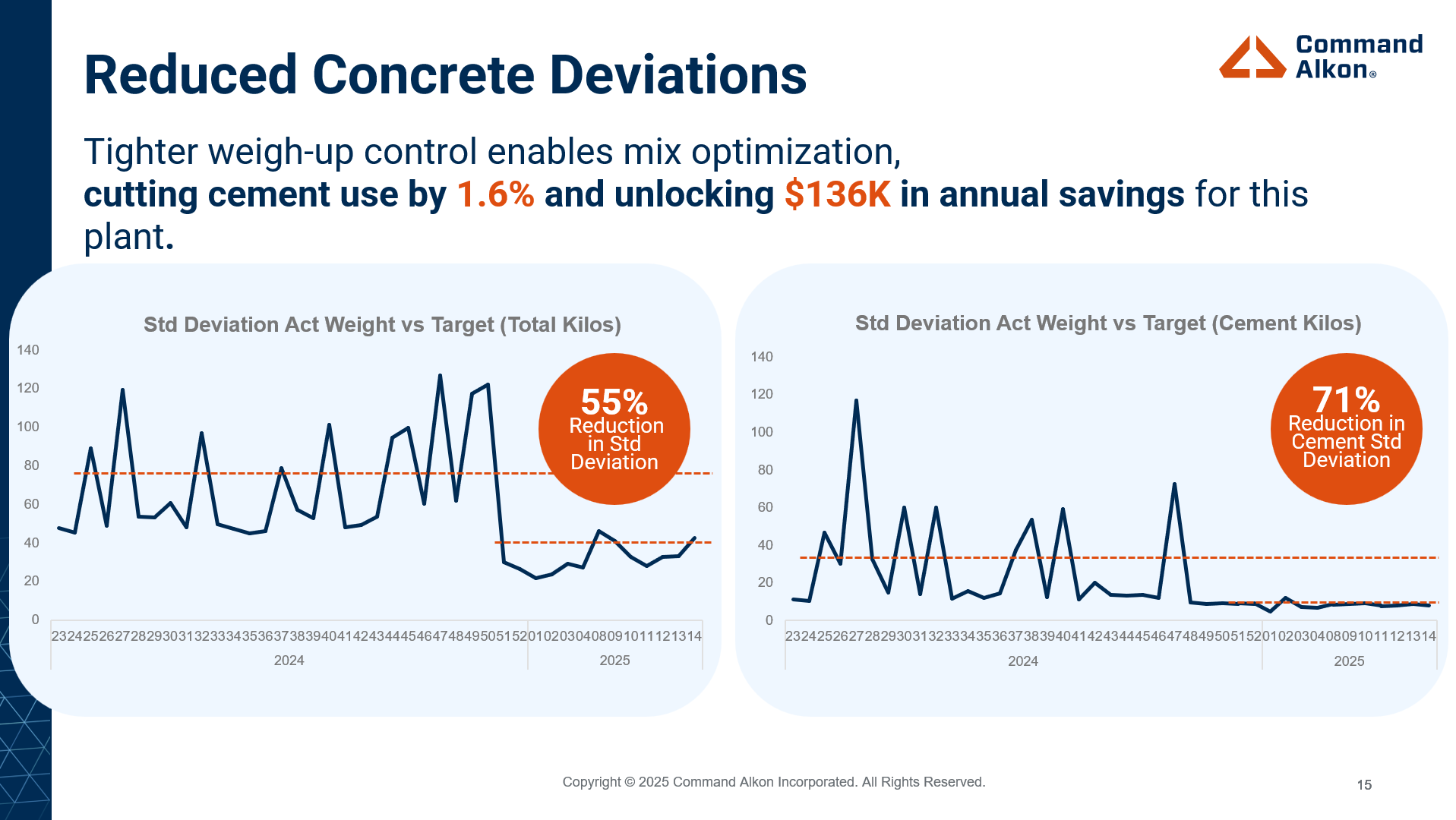

In an industry where margins are tight, reducing material costs is a powerful lever for profitability. Batch AI’s precision-driven approach significantly lowers out-of-tolerance cycles—by as much as 27 percentage points in real-world use cases. This means less wasted material and more predictable batch outcomes. Some plants have reported material cost savings of up to 57% per cubic meter.

Moreover, Batch AI empowers you to optimize mix designs. Instead of compensating for plant inefficiencies with conservative recipes, you can create leaner, more cost-effective mixes while maintaining quality. One customer saved $136,000 annually through optimized cement usage alone—a testament to the system’s value.

» Jump to 14:48

Don’t Wait to Gain a Competitive Edge

In an industry where efficiency, reliability, and cost control are key, Batch AI gives you the tools to stay ahead. Whether you’re navigating labor shortages, looking to streamline operations, or aiming to reduce material costs without sacrificing quality, Batch AI offers the pathway to measurable results.